Instant quotes on made-to-order custom sized knit shade sail covers

For over 30 years, proudly handmade in America custom sized knit sunscreens for awning, cabana, canopy, lanai, patio or pergola cover, livestock and garden shade, pond and tank cooling, water treatment plant temperature control, and hail protection. All of our high quality commercial grade shadecloth is fully knitted and lock-stitched to prevent unraveling. We do not sell cheap agricultural grade woven sunfabric since woven shade netting will unravel when cut or torn. Our time-tested lockstitch knit outdoor-rated, long-term UV stabilized polyolefin fabric is free from hazardous ultraviolet radiation protectant surface coatings. You can expect to see at least eight to ten years of service from one of our properly installed panels and much longer when canopy is cleaned and removed in the winter. Simple exposure to sunlight is not what determines longevity, but rather avoiding abrasion and snagging damage. Laced into place taut with braided rope underneath the trellis is best practice to reduce movement and abrasion for a longer service life. Please read our installation and design tips page and email us with any questions or design concerns. Best wishes for your sunshade project.

One-piece construction never any visible 'factory seams' on our knitted panels

20, 26 & 32 foot wide rolls have loom splice covered with a grommeted pinch pleat

Recommend ordering at least 6 inches smaller than your framework interior

Allow room to lace perimeter taut with rope and possible production variance

+/- Three (3) business day lead time to produce your panel this time of year

For Lowest Price... Width* is the rectangle dimension closest to stock roll width

Reversing the Width* & Length* dimensions on the quoting form sometimes saves money

For instance: order 23' Width by 13' Length (not 13' by 23') for less waste, slitting & GPP

Rectangles over 1000 square foot finish dimension are personally quoted

$150 minimum delivered price for single panel with duplicates discounted

Email us for a personal quote on multiples of different size sunscreens

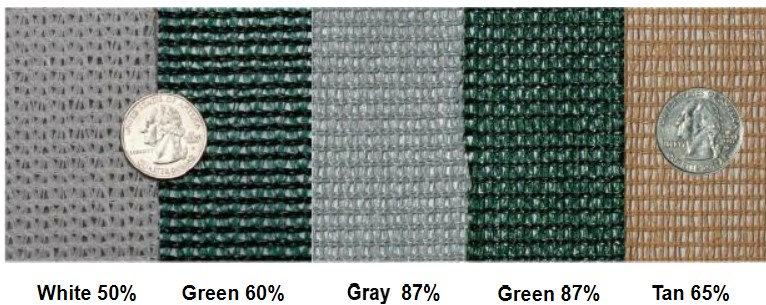

White 50% is a bright paper white not dark, as it appears for contrast highlight

Sample swatches can be mailed for no charge. Please email with a list of fabrics.

Tan & Black 65% knit is our only fabric with two colors of thread. Functionally, either side can face the sun, it's just an aesthetic choice, like how it looks from a distance.

Reinforced 'factory hem' edge shown atop Tan & Black swatches is common to all of our fabrics. Knit shade material is lockstitched to prevent raveling when cut or torn.

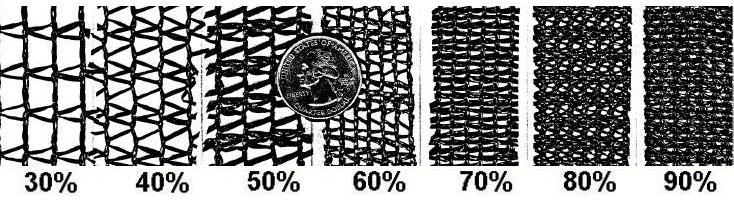

Black 30% to 90% knit density are shown below with all stocked in 6, 8, 10, 12, 20, 26 & 32 foot roll widths.

Gray 87%, Green 87%, Tan 65% and Tan&Black 65% in 6 & 12 foot wide rolls

Two (2) 12 foot pieces of colored fabric are sewn together with pinch pleats for up to 24 foot wide

White 50%, Green 60% and Black 30% to 90% in 6, 8, 10, 12, 20, 26 & 32 foot

8 foot is not stocked in Black 30% or 40% or Green 60% - White 50% is not in 8 or 32 foot width

Email us for a quote on panels wider than 32 foot - We can sew two pieces together

* Pergola & patio covers are usually at least 60% with 80% Black knit being the most common

* Swimming pool leaf covers use 70% or 80% to trap smaller leaf debris and cool water temperature

* Koi ponds tend to be as low as 30% or 40% allowing small debris to pass but warming water more

* Privacy screens with single layer 87% or 90% knit density are private from a distance and at angle

* Wind screen panels tend to be 70% up to 90% depending on need for privacy and wind blockage

* Hail protection panels are usually at least 50%, or more when sun and hail protection is desired

* Spider diaper curtains in 80% or 90% hang under boat dock roof to protect against spider poop

* Greenhouse & solariums like the 50% White knit for moderate sun blockage with ambient light

* Bug screens 50% White, 60% Green or 70% Black for most insects and 80%+ for small bugs

* Paintball nettings are at least 40% knit to keep liquids and small debris from passing through

* Bird netting uses 30% Black knit to provide heavy-duty protection for berries and fruit trees

* Water treatment plants use 80% or 90% knit for algae control & chlorine contact channels

Black 80% knit is the most popular choice for patio shades and pergola sun covers

White 50% and Green 60% knits are common practice in greenhouses and gardens for more direct, diffused and ambient light. Both are much the same knit density as Black 70%, but more translucent for lower shade factor percentage rating. If you want to 'brighten' an area, the White 50% is very white, refracting a much larger percentage of ambient light. Green 60% knit is common practice for outdoor seating areas where diffused, lower ambient light levels will have an interesting 'calming' effect, rather than 'active' ambient white or 'sedate' black. Cooling effect is largely the same regardless of fabric color at the same percentage. Open knit, even on 90%, allows heated air to pass back up through, not trapping heat underneath like a tent or solid tarp. Plus, water can pass through to avoid stressing the patio cover for greater longevity.

Description on the quoting form above is overall FINISH outside-edge to outside-edge corner measurements that we do our best to make for you. Panels are cut down from larger roll widths, allowing extra inches of fabric to fold and sew hem for finish dimension specified. Quoting form description alerts when ordering stock roll width and finish dimension is anticipated to be less than entered. Sewn perimeter hem tape webbing installed on all four sides of canopy does not stretch. Denser knits have minimal interior 'pillowing' stretch under normal, adequate tension. Covers are generally ordered at least 6 inches overall smaller than interior of framework (or cable perimeter) and then laced with rope from every grommet, around all four sides. For instance: framework (or cable network) 12 foot by 12 foot interior measurement would normally see panel ordered no more than 11 foot 6 inch by 11 foot 6 inch overall. Perimeter gap area allows trampoline-style rope lacing and wiggle-room for possible production variance. Avoid 'static fastening' directly through hem or grommets with staples, screws or hooks since there is no room for variance and no ability to adjust tension. Static fasteners are too unyielding. READ THIS PAGE for sizing guidelines, pergola cover installation tips, and design details.

Custom sewing options: odd shapes, triangle sails, open-end sleeve pockets

Sunscreen parts: locking clip fasteners, batten hem tape webbing, sewing repair kit

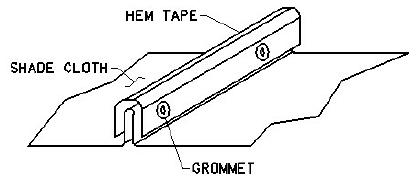

Hem Tape, Grommets, Pinch Pleats, and Double-Layer panel options

BLACK HEM TAPE is 2-3/4 inch wide solid webbing that is folded over, folded fabric and sewn in place for 1-5/16 inch wide 'taped' perimeter hem. Black is the only color available and hem tape must be installed before grommeting. Quoting form finish dimensions of 'Width' and 'Length' are measured from outside-edge to outside-edge of the perimeter hem. Finish Length dimension is never affected by folding of the hem since 2-3 inches of extra material is cut to allow finishing at your desired measurement. Same applies to the Width when we can trim 2-3 inches extra for folding hem. Finish Width will only 'lose' 2 to 3 inches when a stock roll width is ordered and the quoting form description will detail it. For instance: order 12 foot finish width and we start with 12 foot stock for finish likely 11 foot 9-10 inch after sewn hem is folded, but order 11 foot 8 inch finish width and there is enough extra fabric to finish at 11 foot 8 inch.

BRASS #4 GROMMETS are 1 inch outside diameter (quarter coin) with 1/2 inch inside diameter hole. Installed approximately one foot on center to all four sides. Special grommet placement is not available. Corners are double-grommeted as seen here for maximum strength and best longevity. Grommeting begins in one corner, then proceeds on all four sides in turn.

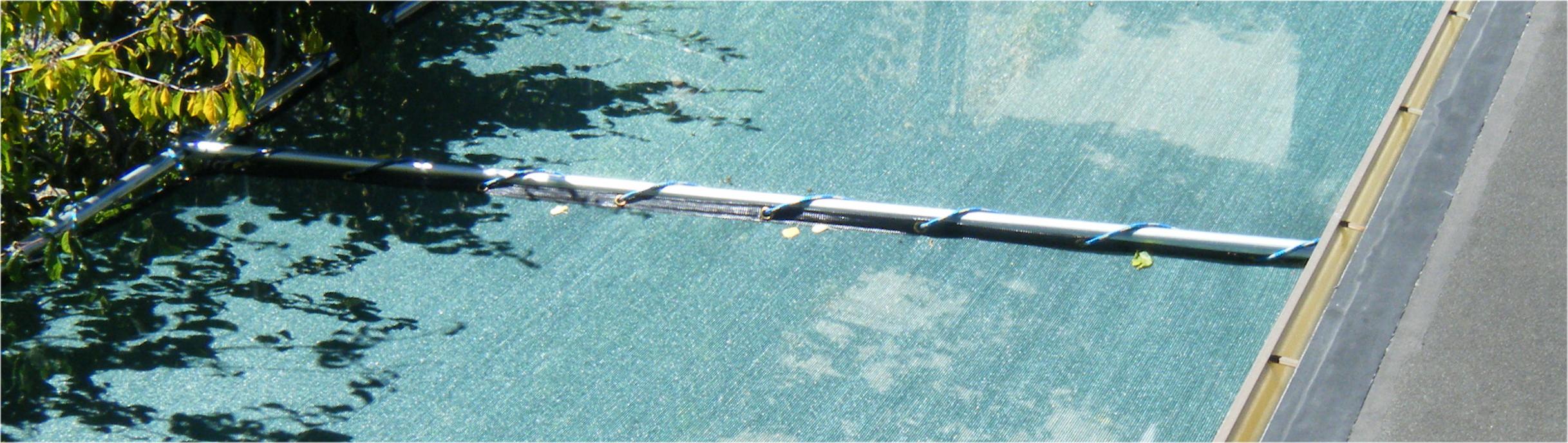

GROMMETED PINCH PLEATS are a nice engineering touch on any size panel. Detailed below, GPP are identical to perimeter hem, but located across the middle or down the center. Pinch pleats are grommeted approximately every foot for stringing a support cable or lashing to framework. GPP are key to longevity by keeping panels taut and avoiding abrasion damage.

DOUBLE LAYER PANELS with two pieces of fabric sewn together is an option for extra privacy, strength, and wind or sun block. No GPP on double layers.

Grommeted Pinch Pleats for best engineering on larger covers

Grommeted pinch pleats at $2 per foot are standard practice on any panel over 12 foot in either dimension. Canopies over over 12 foot wide require one GPP in the center to cover loom splice found on 20, 26, and 32 foot wide stock roll widths. The option exists to have three GPP, each equally spaced, on panels wider than 12 foot. Panels 12 foot width or less, do not require a GPP, but commonly have one at least one in the center, if not one GPP every 8 to 10 foot. Grommeted pinch pleats are not installed much closer than six foot on center. A pinch pleat is made in middle of panel by folding 2-3/4 inch wide black solid hem tape webbing over 'pinched' tab of 2-3 inches folded material and then sewn for about 1-1/4 inch top to bottom pinch pleat. Finish Length dimensions are never affected by folding of the pinch pleat since extra material is cut.

GPP are folded, sewn and reinforced stand-up seams with black hem tape webbing identical to the perimeter hem. Pinch pleats provide exceptional additional engineering strength and stability to any size panel, even when grommets are not laced to framework or supported by stainless steel cable. We MOST HIGHLY recommend adding a center grommeted pinch pleat to any size pergola cover for the sake of longevity.

lifetime UV stabilized without any coatings

All of our heavy-duty fabrics are knitted, never woven, long-term UV stabilized without coatings. Outdoor-rated polyolefin, lock-stitched knit does not unravel when cut or torn. All stock widths have a dense, fully-bound, knitted lockstitched factory edge. Beware of cheap Chinese and agricultural-rated woven fabric which easily unravels when cut or torn. Endless uses for sunscreen sails as pergola shade cover, patio canopy, playground shading, nursery plant and hail protection awning, water treatment plant tank or pond cooling, paintball or golf course fencing, privacy curtains and sun drapes, dust and wind screens. One year manufacturer warranty on defects, but you can expect at least eight years of service from one of our properly installed panels and much longer when canopy is cleaned and removed in the winter. It's not simple sunlight exposure that determines longevity, but rather avoiding abrasion and snagging damage; proper installation is key. Proudly handmade in America for over 30 years, not sewn in China and then flown to the United States like other companies. Shade material engineering specifications, product MSDS sheet, and industry-standard free replacement error tolerance.

installation details are key to longevity

To avoid abrasion damage, best practice is to hang panels underneath the trellis, rather than stretch canopy cover across the top of your pergola. Mounting panels atop the trellis or pergola is only preferred engineering when cover is left up all winter in a snowy climate or with flat installations in areas of heavy rainfall. We always recommend installing grommeted pinch pleats to support across middle or center. GPP provide critical lashing points to stop 'pillowing' and movement, greatly increasing longevity. Panels are single, one-piece construction never any exposed 'factory seam'. Our 20, 26 and 32 foot wide fabrics always have center loom splice covered with GPP for stability and optimal longevity. ALL of our ravel-resistant, fully lock-stitched knit densities will allow hot air to pass freely through, not trap heat and humidity underneath canopy like a solid tarp or tent roof. Rain is allowed to slowly percolate through all knits when installed on a flat surface to avoid weight stress from puddles forming atop like a solid tent tarp. READ THIS PAGE for sizing guidelines and installation tips.

rope and steel cables are not sold here

We do not sell any rope, given the endless options. Best practice is using 5/16 or 3/8 inch diameter braided rope to support the 1/2 inch diameter #4 grommet holes. Sizing up to 3/8 inch diameter is a nice touch, but a slightly smaller diameter 5/16 inch rope is easier to lace on panels much longer than 20 foot. Do not use bungee cord, shockcord, or any other braided elastic rope which will degrade quickly in direct sunlight. Twine or paracord at 1/4 inch, or smaller, generally does not have adequate 'give' and concentrates wind loading stress on a much smaller portion of the grommet. A soft double-braided marine grade rigging rope is best, but any UV resistant solid-braided rope is adequate when the panel is not being taken down seasonally to protect longevity. Cheap rope has a very 'stiff feel' and tends to kink when lacing, making it more difficult to reuse. Better quality rigging rope has a very fluid feel for easier installation. There is no standardized 'rating' system, but sail rigging, industrial safety, and rock climbing companies generally have the highest quality UV resistant rope. To calculate how much rope you will need, assuming +/- four inch perimeter lacing gap, allow for at least 3 extra inches per foot. For instance: a 20 foot by 20 foot panel is 20 feet x 4 sides = 80 feet x 1.25 = about 100 feet of rope.

fire resistant shade fabrics are not sold here

Be well aware of what is (not) being advertised with 'fire resistant' shade fabric. Read the fine print. Exposure to direct sunlight usually limits fire-resistant performance to only a few months. Research the laundry list of chemicals being used in manufacture and you will not want to be sitting underneath when those fire-resistant coatings start flaking off. Safety and health regulations are very loose for 'outdoor' versus 'indoor' fabrics. Poly knit fabrics are not fire-rated but they tend to simply melt (not burn) while fire-resistant materials generally resist high temperatures until they finally burst into flame.

solid tarp tent tarpaulin are not sold here

We do not sell any solid, waterproof tarpaulin 'tent covers' since they are not as effective at keeping a patio or pergola cool. Without holes in the fabric, like our knitted shade cloth, heated air cannot pass back up through. Trapping heat underneath like a tent and allowing rainwater to puddle atop greatly decreases longevity. A knitted shade panel will dramatically slow rain down, but even when installed taut on a steep slope over 45 degrees, not all of the rainwater is going to run off the sides. Given the relatively short life expectancy of solid waterproof poly tarps that allow rainwater to puddle, we recommend roofing the pergola or trellis instead when you require the covering to be 'waterproof'. Metal and Lexan roofing panels are lightweight, economical, and much longer-lasting than tarpaulin, but they can be insanely noisy in a rainstorm. Canvas tent tarps are expensive, dirty, and a pain to keep oiled. And 'heavy-duty waterproof poly tarpaulin' are lucky to last a year in direct sunlight with cheap heat-seamed joints and edges, not fully sewn hems like our knit shade panels. Beware of tarpaulin UV and fire resistant coatings which are invariably toxic and constantly flake off as the tarp ages.

Last updated on April 13th, 2024