Colorado only - greywater disposal system non-electric kit

Greywater disposal systems provide for a care-free, non-electric, do-it-yourself, residential graywater solution. Protect your septic tank and leach field longevity by disposing of greywater separately. Even mild all-natural biodegradable soapy water kills septic tank bacteria, slowing digestion and decomposition of toilet paper and solid waste. Diverting at least the washing machine water to a greywater disposal system will save your septic system from being pumped as often and prevent catastrophic leach field failure. Always check with your building department to confirm local regulations prior to planning any septic (greywater) system to confirm what is required for your property. For over 30 years, we have been providing graywater systems with excellent feedback, but with 64 uniquely regulated counties in Colorado, and an infinite variety of site and soil conditions, we cannot predict what will be required by the building department on your property. The Natural Home is not an engineering firm; we do not provide any engineering services, soil testing or on-site work.

Delivery is FREE within about a 50 mile radius of central Denver. Or you can will-call pick up in person at our central Denver area warehouse with a pre-paid order. North to Fort Collins and Greeley, South to Franktown and Monument, East to Deer Trail and Tampa, West to Georgetown and Silver Plume, and SouthWest to Bailey and Conifer. Delivery slightly outside this free shipment radius may be possible for an extra fee. We can normally schedule an AM or PM delivery with at least three days advance notice, weather permitting. Designated receiver must be on site and waiting with machinery to unload septic tanks with the installed lifting ropes. We do not ship these greywater system products outside of Colorado. Outside of Colorado, please contact the manufacturer at InfiltratorWater.com or info@infiltratorwater.com or 800-221-4436.

Prices quoted here are when paid with MasterCard or VISA credit card

5% Discount for bank wire, cashier's check or US Postal money orders

$2057 for this example credit card and $1954.15 with 5% cash discount

Typical system includes the following parts:

$559 for 12* Infiltrator Quick4 chambers

$120 for 4* Infiltrator multiport endcaps

$1027 for Infiltrator IM-540 settling tank

$80 for at least one 12 inch tall riser

$47 for the optional safety star grid

$10 for a 4" grommet at outlet hole

$107 for greywater filter assembly

$107 for flow director splitter valve

possibly plus some geotextile soil fabric

* Twelve Infiltrator Quick4 chambers (two runs of six) is generally the minimum for a residence. You may be allowed to install less than twelve, but having at least 144 square feet is best practice for sewage treatment and installaton longevity. Required field size will vary based on local regulations (equations used), flow rate (water usage), soil composition, and percolation rate. Chambers are generally given +/- 30% field size reductions over perforated pipe-in-gravel leach fields. Plus, graywater has no solids present (no toilet waste or garbage disposal) so it should qualify for additional size reductions.

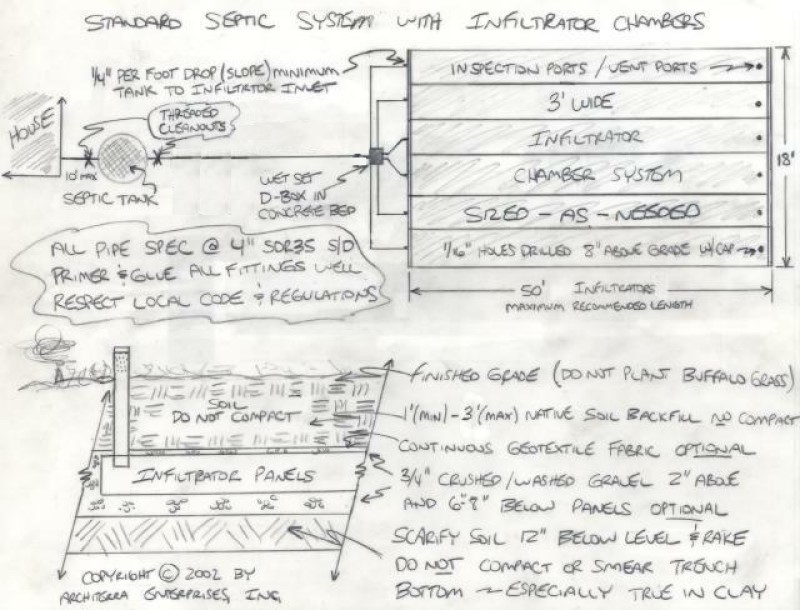

do-it-yourself design tips and rules of thumb for installation

* Always install a settling tank with filter in-line before leach field or drain pit

* Greywater tank up to 10 feet away and leach field 20+ feet from foundation

* Avoid exposing graywater tank lids, covering with gravel, pavers, or mulch

* Always install a cleanout in sewer line near home foundation for servicing

* Effluent pipe may slope more than 1/4 inch per foot since there's no solids

* Bed all pipe and tank in at least six inches of gravel to prevent frost issues

* Never drain directly atop bare ground or spray greywater with yard sprinklers

* When reusing graywater for plants, add nitrogen since that nutrient is missing

* Never use 'septic treatments' as they do more harm than good to leach field

* Use liquid soaps and avoid harsh detergents, bleach, disinfectants & cleaners

* Never install geotextile fabric on the bottom of leach pit or drainage trench

adequately sized for any residential site

Our NSF/ANSI certified standard #46 greywater filter (only sold with greywater system) has a built-in gas deflector on bottom provides secondary 1/2 inch filtration to prevent larger solids from entering the filter area inside. The patented flow reduces the trapping of solids by allowing solids to slough off and fall back into tank for further digestion. The 1/16 inch filtration slots, rather than mesh screen, provides much less surface area for solids to attach and promotes sloughing action. Filter features a locking tab to securely lock the filter into housing tee, preventing any chance of 'floating' and allowing solids to pass by. Easy to rinse off when you inspect the settling tank and the filter never needs replacing.

cold climate installation considerations

The main consideration in a cold climate is keeping frost from penetrating down into soil surrounding the settling tank. Typically, this entails covering the area around tank (surface above) for at least three to four feet with a heavy duty tarp to prevent moisture (frost) from being driven down to surrounding soil. Then place an at least 2 inch thick sheet of blueboard EPS foam insulation directly above tank. You cut hole in center of sheet to slip circle of foam out for gaining access to settling tank lid. Dry soil is key to maintaining warmth since frost only penetrates down into moist soil. Burying the system deeper is always an option to help in cold climates, but a foot or two for the settling tank is typical.

With moving water, especially greywater with some warmth and biological activity, you don't have to worry about freezing issues with proper installation. If you are not using the system during winter months, you should remove the sieve filter from outlet to prevent any chance of freeze damage. But when system is used daily, water is constantly being refreshed and much less susceptible to freezing. Key is a well-bedded tank in plenty of +/- 3/4 inch gravel. In cold climates, install at least one foot of gravel under and around the settling tank to prevent sodden, frozen soil (frost) from touching the tank sides. In extremely cold climates, the settling basin lid and surrounding area can be covered with tarp and 2 inch foamboard insulation and then buried at least one foot under finish grade. While possible to install a riser extension to bury the settling basin deeper, it is not necessary or beneficial to bring the basin lid all the way to the surface. Even in the warmest climates, you should at least cover the lid with mulch to protect plastic from UV sunlight damage and make it easier to uncover when checking tank and filter yearly. The leach pit should never be a freezing concern unless the soils are not percolating properly or not enough gravel is placed under and around it. In poor percolating soils, one just digs a larger and deeper leach pit and installs more gravel to allow room for percolation (one foot is a bare minimum). Key with any installation is to loosen 'scarify' the soil up to a foot below the base of the leach field.

high groundwater & settling tank floating

High groundwater flooding the settling tank hole can cause the tank to float in extreme situations. The settling basin is heavily ribbed to allow wrapping chain(s) around the outside and securing to a concrete pad underneath. Best practice is to use a chain large enough to pass several sticks of #3 (3/8 inch diameter) rebar through the links. Ideally, one uses 2by6 lumber to build a form larger than the tank base and then pour mixed concrete atop the chain and rebar. Use 'rebar chairs' or bricks to keep the rebar +/- 2 inches off the bottom of the hole so they end up in the middle of the concrete pad. Best to have several inches of gravel in the base of the excavated hole to prevent soil from mixing with the concrete. Should you have standing water in the base of the excavated hole and not be able to remove it for the pour, it is possible to just lay the chain(s) with rebar in the base of the excavated hole (atop gravel) and set a single layer of bags of Sakrete concrete mix atop. The bags will absorb that water and set solid enough to act as ballast for the settling tank. Certainly many ways to improve on the basic installation noted here, but this should suffice to prevent the settling tank from floating due to high seasonal groundwater. Keep in mind that the tank is always 2/3 full of water. Ultimately, running a French drain from the settling basin hole to 'daylight' is the best solution, but anchoring should work fine. Unless required by local building code, there should not be any need to seal the joint between tank and riser, unless the tank lies in a floodplain. Water level is well below the riser. Any silicone or butyl caulk will work on these polyethylene basins.

disposal systems without any settling tank

While possible for a greywater system to not have a settling filter basin tank and just install numerous Infiltrator chambers in-series, longevity is always compromised. Grease traps under sinks, filter on the washing machine discharge, and screens in all sinks will help reduce sediment and fats, but not eliminate the need for a settling tank that can be pumped. Your county health department dictates local rules and building regulations, but generally, one must always have a settling filter basin to catch solids and fats. Should local code not apply to your project, it is still very wise practice to prevent particulates from entering the leach field or pits (drywells), forming bio-mat, and eventually clogging soil and stopping percolation.

greywater recycling systems are possible

Please take this link to a detail page with typical greywater leach field sketches. Any greywater disposal system can very easily be converted into greywater recycling system later. A row of privacy bushes or a small orchard are best methods to reuse greywater. A fruit tree can easily uptake well over 15 gallons per day. And the pipes do not need to be pressurized. We do not sell individual pipe fittings or electrical components such as pumps, alarms, and gate valves. Any additional system parts, pipe or fittings you may need are locally available at Lowes or Home Depot. When you have to lift the effluent with a pump (or pressurize lines) Liberty makes a nice pump. Control and alarm panels are generally provided by the project electrician since they warrant the install. Shut-off valves (electric or manual 'gates') are available in an endless variety online. For instance, a mid-range shut-off valve is the 'Valterra 6401' in 4 inch a PVC gate valve slip by slip hub.

NSF 350 and 350-1 devices are not sold here

Sterilizing greywater on-site to the point where it can be reused for above-ground yard sprinklers or flushing a toilet is rarely cost-effective. Should your county require sterilization of greywater effluent to meet local building codes, an economical option may be to add an in-line "automatic chemical feeder" for chlorine cakes. Building department (or your engineer) is responsible for helping you find the correct part, but can be the same as used for chlorinating swimming pools. National Sanitation Foundation NSF/ANSI standard 350 and 350-1 onsite graywater reuse systems exist, but they are complex, expensive toys with way too many electrical components, moving parts, replacement filters, and fixtures that will eventually fail and have to be repaired, then good luck finding replacement parts. And then there is the family health and public liability risk from a poorly maintained NSF350 or 350-1 onsite graywater reuse system when surface watering your lawn. Sterilizing greywater on-site to the point where it can be reused for above-ground yard sprinklers or flushing a toilet is simply not sensible or even remotely cost-effective. Even drip irrigation systems are not practical due to calcification problems with small spray holes on drip lines. Greywater is, however, excellent for reuse in rural passive, non-electric direct disposal or sub-surface root-zone irrigation of trees, privacy hedges, and ornamental planterbeds. Low-tech gravity drainage 'septic' settling filter basin tank systems like our greywater kit, have been standard practice for generations. The lack of bacteria and nitrogen 'loading' is what allows for a smaller footprint leach pit, rather than larger pipe-in-gravel septic leach field.

local building codes and plan engineering

"Are we allowed to install this greywater septic system on our property" and or "what size hole does the leach pit have to be" are not questions we can answer for you. We have been providing much the same non electric greywater system parts for over thirty years now, but we do not follow constantly changing city, county, and state building regulations. We encourage clients to mail copies of their greywater system plans for our free review with purchase of a system. But understand that The Natural Home is not an engineering firm; we do not provide any engineering services, soil testing or on-site work.

Flow director valve allows one half of your leachfield to go fallow for a few months to revitalize soil, prevent overloading, and reduce the growth of bio-matting. This is a critical design advantage. Graywater effluent can be split 50/50 between the two outlet pipes OR you can alternate the flow 100% to one side. Three director valves will allow splitting between four separate lines, giving you the option of allowing 1/4 of leach field to go dry seasonally. Flow director splitter valve kit for $107 comes complete with adjustment handle, riser, coupler, and four inch threaded access cap. Special staggered hubs on the ‘versa-tee’ will accommodate both Sch40 or thin wall SDR35 sewer drain pipe. Distribution boxes and tee fittings off-level by as little as 1/8 of an inch will be drastically less than equal 50/50 split. But with director valve, even at 1/8 inch tilt, flow directer delivers relatively equal flows (+/- < 1.3%). Click for flow director splitter valve install tips.

Last updated on February 6th, 2024