Locking clip anchor fasteners to mount any tarp or fabric to anything

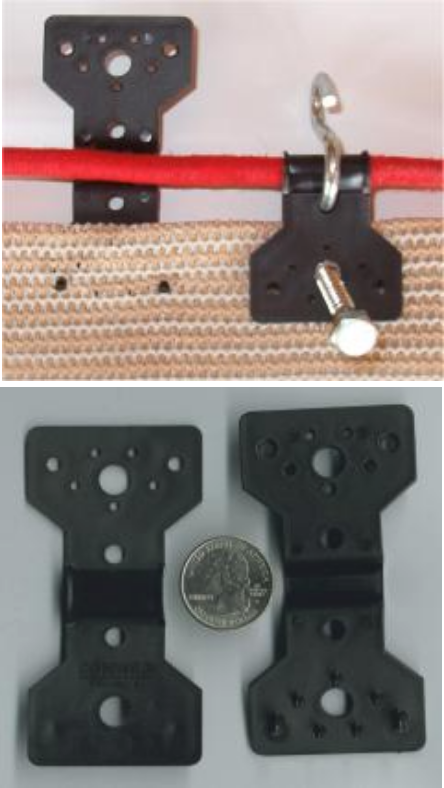

We do not sell brass grommet kits or galvanized nailing plates, since these locking clip anchor fasteners are so much more effective and longer lasting on knitted or woven shade cloth panels, geotextile soil fabric, and landscaping weed barrier material. Our commercial grade locking clips are heavy duty with longer barbs than 'residential grade' locking clips found in big box stores. These professional-duty commercial grade UV stabilized plastic locking clips are 1-1/2" wide by 1" tall and will easily penetrate at least two or three layers of thick material for a nice strong folded hem. With sewn reinforced hems, a scratch awl is best used to punch starter holes for the main barbs. Specifically designed for tying guy wires off or wrapping the fabric onto chain link fence, cable, or rope (up to 5/16 inch diameter). Large surface area, unlike a grommet, ensures your tarp will not be damaged when pulled taut. They have TWO front holes for maximum versatility, a small 3/16" hole at top for hook (pictured) or screws and a larger 5/16" hole in middle for lag bolt (pictured). The pass-through opening across top/center will hold up to 5/16" diameter cable or rope (red rope pictured). Top image is a clip being installed, showing several options. Note we do not supply the S hooks, lag bolts, or rope pictured. Bottom image is front and back of a locking clip. You can even put one on each side of fabric, instead of folding over the edge, for a center-mounted fastening point in the middle of a panel. Fold cut edge of material over two or three times and and snap clip into place. Barbs on one side lock into holes on the other side of fastener. These anchor clips are a very quick and effective answer for installing tarps and windscreens on chain link fences to stop fabric movement in the wind.

36 count bags* of our UV stabilized poly locking clips

$15 per 36 count bag (41.6 cents each) up to 3 bags

$13 per bag (36.1 cents each) at 4 bags (144 clips)

$11 per bag (30.5 cents each) at 7 bags (252 clips)

$10 per bag (27.8 cents each) at 10 bags (360 clips)

$8 per bag (22.2 cents each) at 30 bags (1080+ clips)

Bulk discount pricing will display in shopping cart

* Orders for more than 108 clips will ship loose in box

Email us for 3600 bulk boxes at $720 (20 cents each)

FREE Shipping with service to 48 contiguous states

1 bag First Class, 2-4 bags Priority Mail & 5+ bags UPS

Always in stock, shipping promptly by next business day

Fasteners, fabric, and red rope are not included with clips

S hook, lag bolt, red rope, and fabric are for reference only

Two front holes: 3/16" top (hook) and 5/16" middle (lag bolt)

Pass-through across top (red rope) 5/16" cable or 3/8" rope

Shown above, locking clips are laced with rope to 1-3/8 inch diameter galvanized pipe shade trellis frame made with locally available 'top rail' fencing pipe. Home building material stores commonly stock such pipe for making chain link fences. Below, our locking clip anchor fasteners have been attached directly to the wire mesh fencing on a gate. Our commercial grade, heavy-duty locking clips are custom made for securely attaching knit shade material directly to chain link and wire mesh fencing for privacy, animal enclosures, dust control, visual barrier, wind screen, or sun screen.

Wind can whip a loose lanai cover or shade canopy, causing damage. That's why locking clip anchor fasteners are traditionally placed about one foot on center around the perimeter. You can also install locking clips in the middle of a panel, by 'mating' them, with one on each side of the shade fabric. NEVER never attempt to pull a panel from the corners only, especially not with a fixed fastener, like a screw or nail. Best practice is to lace all four sides to the structure, using rope from every clip, to spread the stress out evenly. To anchor a panel with fixed fastener, instead of a rope, presents an undue amount of stress and no 'give'. The more evenly stretched and supported, the stronger the panel and structure it is attached to. Shade panels are typically laced to a frame: tie rope or galvanized cable to corner post and run it through a grommet, around the trellis or pipe frame, back through the next grommet, and back around the structure... all the way to the corner, where you pull it tight and secure (often with a turnbuckle to tighten as need be). When not lacing around the structure itself, a pipe, board or fasteners (horseshoe nails or eyelet screws) can be installed on structure and then the panel laced to it. Instead of horseshoe nails or eyelet screws, it is common to simply install deck screws at an angle into top of wood pergola (leave about an inch exposed) and then lace panel from grommets to exposed, angled screw shanks. And keep in mind that the anchor points atop trellis do not have to line up exactly with the clips... nice, but not necessary. We do not sell the pipe, rope, cable, turnbuckles, horseshoe nails or eyelet screws, as these items are commonly available at any building supply center.

Wood trellis, arbor, patio or pergola frames can fasten fabric directly to the rafters or lace the knit shade material with rope from locking clip grommets to nails or screws on the pergola frame. Taut installations will prevent movement and abrasion. Year-round installations over wooden trellis, lanai and pergolas are commonly 'raw material' plain cloth stretched atop and held in place with 1by2 wood strips (batten boards) around the edges, sandwiching the plain cloth between the trellis and outer trim wood (the batten board). An improvement is to roll the 1by2 up into the material, then nail it in place. This technique makes it very easy to apply lots of tension on the 1by2 rolled up into shade cloth... and to easily let-out a little material by unrolling a bit. Just fold cut edge of material for a mock hem and staple or nail in place. Be sure to use copper, stainless steel, or at least galvanized fasteners to avoid rusting and abraiding the material.

Do not use vinyl coated cables, as the vinyl coating turns yellow and cracks, needing replaced long before the cable fails. Highest strength stainless steel cable is typically advertised 'Aircraft Quality' which allows for using thinner diameter braided. Tip for larger commercial projects with lots of tension on cables is to weld your anchor eyelets so they cannot bend open. The stress placed on anchor points in a long cable installation can easily bend poorly-made eyelet bolts open. We do not sell rope, cable, turnbuckles, or eyelet screws since they are commonly available at your local building supply center. Larger projects can use the assistance of an engineer, but we do not supply any engineering services and cannot offer any local referrals for structural design assistance. Material weighs less than half an ounce per square foot, so weight is not the issue, but rather loft and sail engineering stress as the panel moves and snaps when installed too loose.

Six foot wide knit fabric shown draped along the ugly back-side of an old cedar fence. With small holes in weave, up close you can see through any density/color of shade cloth. But as you move farther away (20 plus feet) and at an angle, it is much more difficult to distinguish objects on other side. Do not expect total privacy from a single layer of any knitted fabric and even with two layers, a person standing with their face pressed against the fabric can see through. All colors resist fading very well and will normally last over ten years in vertical applications, especially when you take the time to design such that abrasion is avoided with panel not rubbing against fence and well supported with plastic locking clips and batten boards, as seen here.

Six foot wide knit shade material used as free-form shade panels, hung individually atop a yacht. By fastening only the ends, installation is weaker and there is more movement, but panels can be easily removed when the wind picks up. Note locking clips are best placed one every foot on center, not two foot centers, as shown.

Heavy-duty black hem tape webbing for sewing reinforced batten edges

FREE Shipping via UPS Ground (USPS Priority Mail for 1 roll)

Only to contiguous 48 states. We ship by the next business day.

Hem ‘tape’ webbing contains no adhesive. There are no adhesive-based repair tapes available that will stand up to sunlight exposure and tarp tension stress for any length of time. This 2-3/4 inch wide, solid batten webbing tape is folded over the edge of folded netting and then stitched into place for a sewn, reinforced hem or repair. Hem tape can be folded atop crease in center or across middle of panel for a pinch pleat. Webbing reinforced hems and pinch pleats make it possible to punch grommets and have them hold along the edge of a patio cover. Best practice is to sew panels with the heaviest gauge UV stabilized marine-grade outdoor ‘upholstery’ thread possible for the machine you are using. For a home sewing machine, this generally translates to about #90 UV thread and a size #16 Ball Point needle. Our hem batten tape is tested and conforms to UL standard 723. We do not sell webbing in less than full roll quantity, except in the repair kit below.

Shade panel and tarp repair kit with hem tape webbing, needles, and thread

Out of stock

FREE Shipping via Priority Mail with US Postal Service.

Only to 48 contiguous states. We ship by the next business day.

Shade panel and tarp repair kit includes: 40 feet of 2-3/4 inch wide black hem tape webbing, 150 yard spool of heavy-duty black upholstery thread, two #18/110 sewing machine needles, and one #18 chenille hand needle. Plus, eight of our commercial-duty locking clips, which are used in place of grommets to avoid damaging knit fabric. And a piece of knit material to test machine tension settings before sewing the panel. Should you need more than 40 foot of hem tape webbing, please drop us an email. Small tears can be repaired with hand needle and thread. Material is pulled together at the tear and chain stitched to prevent unraveling. Avoid using heat for searing or open flame anywhere near a tarp or knit shade panel. A little silicone or butyl caulk will help protect the repair, but spoils appearance. Larger tears are best reinforced with hem tape webbing on a home sewing machine. While possible to create a ‘patch’ by laying one piece of webbing flat on both sides, it is much stronger to repair with a pinch pleat. Webbing is folded in half, atop a crease made by ‘pinching’ material on both sides of the tear. Hem ‘tape’ webbing contains no adhesive. That we have found, there are not any adhesive based repair tapes available that will stand up to sunlight exposure and tarp tension stress for any length of time.

Last updated on July 5th, 2023