Options for odd shapes, pocket sleeves, sewn hem, grommets & pinch pleats

There are endless uses for sunscreen shade sails as pergola shade cover, patio canopy, playground shading, nursery plant and hail protection awning, water treatment plant tank and pond cooling, paintball or golf course fencing, privacy curtains and sun drapes, dust and wind screens. Irrigation maximizing, agricultural shading, and excellent cost-benefit ratio for cooling cattle, sheep, and other animals. Livestock eat more, putting on weight much faster in hot climates when adequate shading is provided. Water treatment plants save a great deal of money by using far less chemicals with much lower evaporation rates. Read this page for sizing guidelines, pergola cover installation tips, and patio shade panel design details.

Custom options: odd shape panels, triangle sails, and open end sleeve pockets

ALL of our ravel-resistant, fully lock-stitched knit densities allow hot air to pass freely through, not trap heat and humidity underneath like a solid tarp or tent roof. Rain is allowed to slowly percolate through all knits when installed on a flat surface to avoid harmful puddling atop. Outdoor-rated polyolefin fabrics are lockstitch knitted, never woven, to prevent unraveling and long-term UV stabilized without any harmful coatings. Stock widths have a dense, fully-bound, knitted lockstitched factory-seamed edge. Beware of cheap Chinese and agricultural-rated woven shade nettings which quickly unravel when cut or torn. You can expect to see at least 8-10 years of service from one of our properly installed panels and much longer when canopy is cleaned and removed in the winter. Exposure to sunlight is not what determines longevity, but rather abrasion, so proper installation is key. Click for fabric engineering specifications, product MSDS sheet, panel warranty, and industry-standard free replacement error tolerance.

Odd shape custom panel quotes are available with sketch

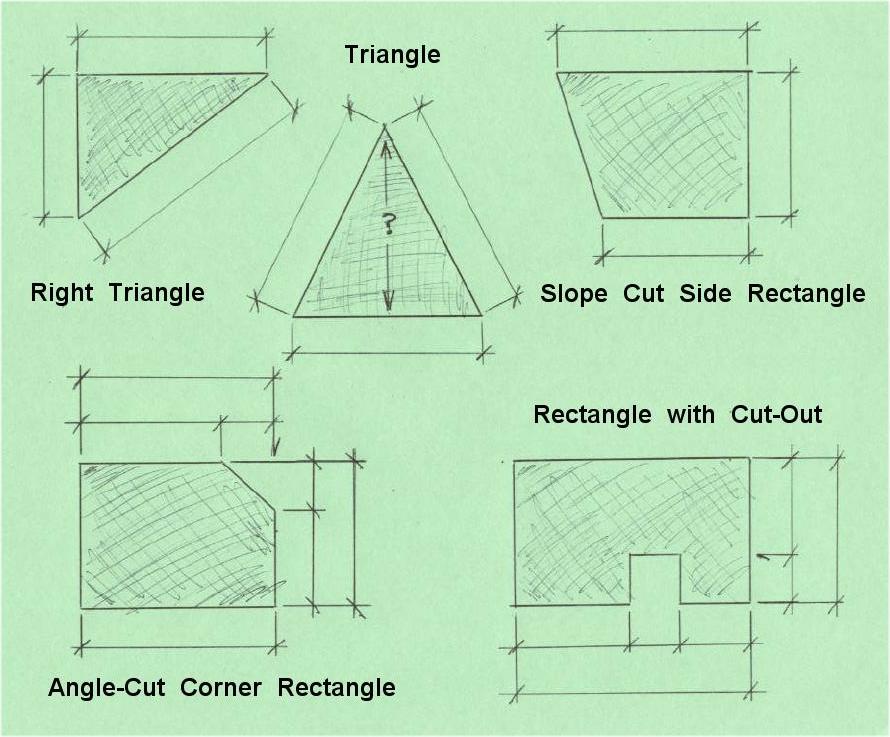

Odd shape panel and triangle sail production is very limited during peak season from Memorial Day through Labor Day. For a quote, please email service@thenaturalhome.com with a sketch in .pdf or .jpeg format (we do not open .docx or .xlxs or .zip files). Full inches only, no fractions with all dimensions in feet and inches, not inches only (e.g., 8 foot 4 inches not 100 inches) per stated tolerances. Specify material choice and need for hem and grommet. Brass #4 grommets are standard about one foot on center all sides with double corners for best engineering support. Custom size triangle canopy covers must specify all three sides PLUS interior altitude, base-to-apex dimension labeled '?' below. No sketch is needed on right triangles since only two sides need to be specified with third side mathematically derived. Only the following shapes are possible to produce and cut-outs must be at least one square foot, not post or gutter size. Open end pockets, double-layer panels, grommeted pinch pleats, and special grommet placements are not allowed on odd shape panels.

Best practice is to specify overall dimension at least 6 inches smaller than the trellis framework or cable perimeter interior dimension to allow for trampoline-style lacing with rope from grommets and wiggle-room for any variance. Denser knits have very little stretch under normal tension and the sewn perimeter hem will not stretch at all, but it certainly pays to provide space to lace odd shape panels properly. No need to over-tighten, stretch and distort a panel, but it should be taut to avoid wind movement, per installation guidelines. Production will do a fine job as always, but please note odd shape panels are not warranted for return, refund, or free replacement for any errors at quoted price.

Single odd shape panels are a minimum $200 delivered price. An economical alternative for odd shape canopy covers is to purchase plain cloth (no hem or grommet) and then cut on-site for optimal accuracy and install plastic locking clips. Cut fabric six to eight inches larger than finish dimension you are looking for and fold edges over several times. Cut edges can be sewn on a home sewing machine, but in practice sewing is not necessary when cut edges are folded over two or three times and clips placed every foot. Our commercial-duty locking clip anchors act as a grommet plus they allow for attaching directly to chain link fencing or running cable along the edge.

Sewn perimeter hem and grommet work

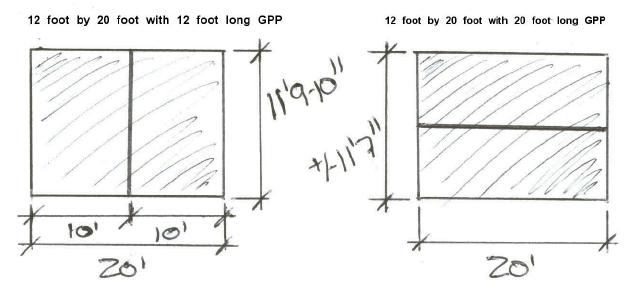

Black color only, 2-3/4 inch wide solid webbing is folded over, folded fabric and sewn in place for 1-5/16 inch wide 'taped' perimeter hem. Quoting form finish dimensions of 'Width' and 'Length' are measured from outside-edge to outside-edge of the perimeter hem. Finish Length dimension is never affected by folding of the hem since 2-3 inches of extra material is cut to allow finishing at your desired measurement. Same applies to the Width when we can trim 2-3 inches extra for folding hem. Finish Width will only 'lose' 2 to 3 inches when a stock roll width is ordered and the quoting form description will detail it. For instance: order 12 foot finish width and we start with 12 foot stock for finish likely 11 foot 9-10 inch after sewn hem is folded. But order 11 foot 8 inch finish width and there is enough extra fabric to finish at 11 foot 8 inch.

standard double grommet corner

BRASS #4 GROMMETS are 1 inch outside diameter (quarter coin) with 1/2 inch inside diameter hole. Installed approximately one foot on center to all four sides. Special grommet placement is not available. Corners are double-grommeted as seen here for maximum strength and best longevity. Grommeting begins in one corner, then proceeds on all four sides in turn.

GROMMETED PINCH PLEATS are a nice engineering touch on any size panel. Detailed below, GPP are identical to perimeter hem, but located across the middle or down the center. Pinch pleats are grommeted approximately every foot for stringing a support cable or lashing to framework. GPP are key to longevity by keeping panels taut and avoiding abrasion damage.

DOUBLE LAYER PANELS with two pieces of fabric sewn together is an option for extra privacy, strength, and wind or sun block. No GPP on double layers.

Brass grommets are standard industry practice for many reasons, primarily longevity. We experimented with other choices over the years, but negative feedback reinforced the use of brass. Black grommets shed their colorant, quickly becoming an eyesore. Aluminum grommets are much too soft, quickly degrading from rubbing abrasion against fasteners, cable and rope. And stainless steel is too dense to properly crimp closed unless produced so thin that they degrade nearly as fast as aluminum. Beware of grommet choices other than brass if you are concerned at all about longevity. Brass takes on a dark patina over time, blending in nicely with the black perimeter hem tape. Black color perimeter hem tape is the only choice available. When we offered color choices, the hem tape never identically matched fabric color and faded at different rates, displeasing clients. The black hem tape gradually fades to a softer gray-black, blending nicely with any color knit.

Grommeted Pinch Pleats are standard practice on larger covers

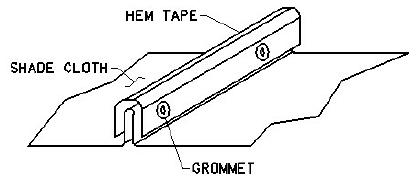

Grommeted pinch pleats are sewn across the middle or down the center for $2 per lineal foot. GPP are folded, sewn and reinforced stand-up seams with black hem tape webbing identical to perimeter hem. Pinch pleats provide additional engineering strength and stability to any size panel even when grommets are not laced to framework or supported by stainless steel cable. We MOST HIGHLY recommend adding a center grommeted pinch pleat to any size pergola cover.

Grommeted pinch pleats at $2 per foot are standard practice on any panel over 12 foot in either dimension. Canopies over over 12 foot wide require either one GPP in the center or three GPP, each equally spaced to allow center GPP to cover loom splice found on 20, 26, and 32 foot wide stock roll widths in knit material. Panels 12 foot width, or less, commonly have one GPP every 8 to 10 foot on center across the width, but at least one GPP in the middle/center of any panel is most highly recommended. Grommeted pinch pleats are not installed much closer than six foot on center, which is optimal for fixed-in-place, laced taut shade panel installations. A pinch pleat is made in middle of panel by folding 2-3/4 inch wide black solid hem tape webbing over pinched tab of 2-3 inches folded material and then sewn for about 1-1/4 inch top to bottom pinch pleat. Finish Length dimensions are never affected by folding of the pinch pleat since extra material is cut.

Brass #4 grommets are installed one every foot along pinch pleat, just like the perimeter hem/edge. This additional lashing (tying to structure) with GPP eliminates lofting and sailing (rising in the wind) and sagging in the middle (pillowing) on larger shade panels. Movement and abrasion against the structure are what eventually causes material failure, not simple exposure to the sun, so keeping a panel taut is the key to longevity. It is not possible to overlap GPP in middle of panel (crossing one over the top of another) and GPP are not available with double layer panels. Exact spacing of GPP is not warranted and special grommet placement is not possible to specify. Professional installers begin large panel installations by lacing the center grommeted pinch pleat to central frame member (ridge beam, cable, conduit, or pipe) and then pulling pergola cover taut across width sides and finally tension across length, towards two ends in-turn.

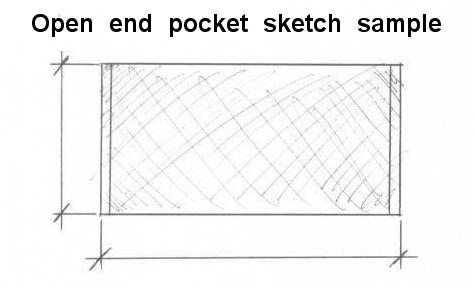

Open End Pockets for inserting rod, pipe, or board through side

Best practice is lacing all four sides of canopy cover with rope from grommets, but we can provide open end sleeve pockets for $2 per lineal foot for passing a rod, pipe, board, or cable through. Fabric is folded over and sewn with reinforced black hem tape batten webbing for an appearance much like pinch pleats. E-mail service@thenaturalhome.com for a quote with sketch in .pdf or .jpeg format (we do not open .docx or .xlxs or .zip files). Full inches only, no fractions with all dimensions overall (including the flat pocket) in feet and inches, not inches only (e.g., 8 foot 4 inches not 100 inches) per stated tolerances. Pocket size is the 'flat dimension' interior net width, not diameter, in full inches only with no fractions. Specify material choice and need for grommets on the other sides. Grommets are not possible to install on top of a pocket. One grommeted pinch pleat can be placed across the middle, parallel with pockets, but GPP cannot run into a pocket.

When converting from diameter of pipe or hanging rod to 'flat dimension' of the pocket, allow room for variance. For example: 1-1/4 inch outside diameter pipe with circumference of 3.927 inch requires at least 3 inch flat dimension pocket since a 2 inch pocket does not allow any room for error. Another example: 2 inch diameter Sch40 pipe with outside diameter of 2-1/2 inch and circumference of 7.854 inch requires 5 inch pocket since 4 inch does not allow any room for variance. Requires a 6 inch flat dimension open end pocket to insert a 2by4 board (1.5 & 1.5 & 3.5 & 3.5 = 10+ inches). Full inches only, no fractions.

Finish dimension and installation tips

Description on the automated quoting form is overall FINISH outside-edge to outside-edge corner measurements that we do our best to make for you. Panels are cut down from larger roll widths, allowing extra inches of fabric to fold and sew hem for finish dimension specified. Quoting form description alerts when ordering stock roll width and finish dimension is anticipated to be less than entered. Sewn perimeter hem tape webbing installed on all four sides of canopy does not stretch. Denser knits have minimal interior 'pillowing' stretch under normal, adequate tension. Panel covers are generally ordered at least 6 inches overall smaller than interior of framework (or cable perimeter) and then laced with rope from every grommet, around all four sides. For instance: framework (or cable network) 12 foot by 12 foot interior measurement would normally see panel ordered no more than 11 foot 6 inch by 11 foot 6 inch overall. Perimeter gap area allows trampoline-style rope lacing and wiggle-room for possible production variance.

Avoid 'static fastening' directly through hem or grommets with staples, screws, hooks, or zip-ties since there is no room for variance and adjusting tension. Static fasteners are unyielding under stress from movement and often damage hem and grommets. If you do choose static fastening, we recommend using 1+ inch diameter fender washers to spread stress out evenly, across entire grommet. To avoid abrasion damage, best practice is to hang panels underneath the trellis, rather than stretch canopy cover across the top of your pergola. Mounting panels atop the trellis or pergola is only preferred engineering when cover is left up all winter in a snowy climate or with flat installations in areas of heavy rainfall. Recommend installing grommeted pinch pleats to support across middle or center. GPP provide critical lashing points to stop 'pillowing' and movement, greatly increasing longevity. Panels are single, one-piece construction never any exposed 'factory seam'. Our 20, 26 and 32 foot wide fabrics always have center loom splice covered with GPP for stability and optimal longevity. READ THIS PAGE for sizing guidelines, pegola cover installation tips, and design details.

Solid waterproof tarpaulin tent covers and toxic UV coatings

We do not sell any solid waterproof 'tarpaulin' or tent covers since they are not as effective at keeping a patio or pergola cool. Without holes in the fabric, like our knitted shade fabric, heated air cannot pass back up through. Trapping heat underneath like a tent and allowing rainwater to puddle atop decreases longevity. A knitted shade panel will dramatically slow rain down, but even when installed taut on a steep slope over 45 degrees, not all of the rainwater is going to run off the sides. Given the relatively short life expectancy of solid waterproof poly tarps that allow rainwater to puddle, we recommend roofing the pergola or trellis instead when you require 'waterproof'. Metal and Lexan roofing panels are lightweight, economical, and much longer-lasting than tarpaulin, but they can be insanely noisy in a rainstorm. Canvas tent tarps are expensive, dirty and a pain to keep oiled. And 'heavy-duty waterproof poly tarpaulin' are lucky to last a year in direct sunlight with cheap heat-seamed joints and edges, not fully sewn hems like our knit shade panels. Beware of 'UV resistant coatings' which are invariably toxic and flake off constantly as the tarp ages. Fire resistant tarpaulin coatings are even more toxic.

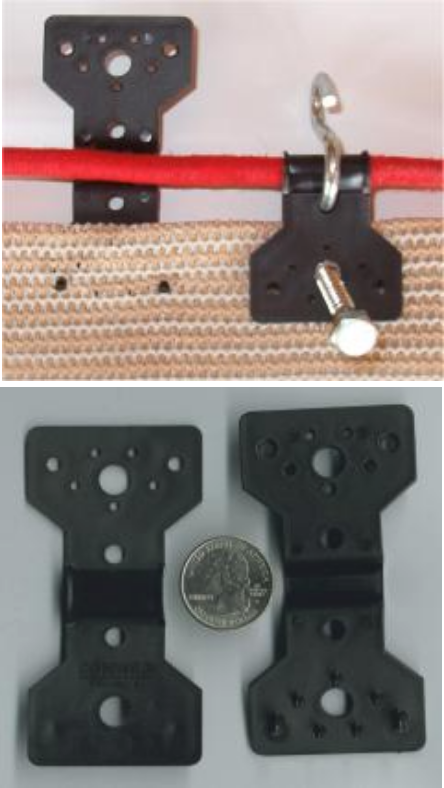

Locking clip fasteners attach any fabric on cable, fence, rope or nails

We do not sell grommet kits or nailing plates, since these locking clip anchor fasteners are so much more effective and long lasting on plain cloth panel pergola covers. Our commercial grade locking clips are heavy duty with longer barbs than 'residential grade' locking clips found in big box stores. These professional-duty commercial grade UV stabilized plastic locking clips are 1-1/2" wide by 1" tall and will easily penetrate at least two or three layers of thick material for a nice strong folded hem. With sewn reinforced hems, a scratch awl is best used to punch starter holes for the main barbs. Specifically designed for tying guy wires off or wrapping the fabric onto chain link fence, cable, or rope (up to 5/16 inch diameter). Large surface area ensures your material will not be damaged when pulled taut. They have TWO front holes for maximum versatility, a small 3/16" hole at top for hook (pictured) or screws and a larger 5/16" hole in middle for lag bolt (pictured). The pass-through opening across top/center will hold up to 5/16" diameter cable or rope (red rope pictured). Top image is a clip being installed, showing several options. Note we do not supply the S hooks, lag bolts, or rope pictured. Bottom image is front and back of a locking clip. You can even put one on each side of fabric, instead of folding over the edge, for a center-mounted fastening point in the middle of a panel. Fold cut edge of material over two or three times and and snap clip into place. Barbs on one side lock into holes on the other side of fastener. These custom size pergola shade canopy cover anchor clips are very effective on chain link fences to stop movement in the wind.

36 count bags* of our UV stabilized poly locking clips

$15 per 36 count bag (41.6 cents each) up to 3 bags

$13 per bag (36.1 cents each) at 4 bags (144 clips)

$11 per bag (30.5 cents each) at 7 bags (252 clips)

$10 per bag (27.8 cents each) at 10 bags (360 clips)

$8 per bag (22.2 cents each) at 30 bags (1080+ clips)

Bulk discount pricing will display in shopping cart

* Orders for more than 108 clips will ship loose in box

Email us for 3600 bulk boxes at $720 (20 cents each)

FREE Shipping with service to 48 contiguous states

1 bag First Class, 2-4 bags Priority Mail & 5+ bags UPS

Always in stock, shipping promptly by next business day

Fasteners, fabric, and red rope are not included with clips

S hook, lag bolt, red rope, and fabric are for reference only

Two front holes: 3/16" top (hook) and 5/16" middle (lag bolt)

Pass-through across top (red rope) 5/16" cable or 3/8" rope

Repairing a torn shade panel typically requires sewing

There are not any adhesive 'repair tapes' or patches available that will stand up to sunlight exposure and tensional stress for any length of time. Short small cuts on knit shade covers are best pulled together and chain-stitched by hand with needle and thread. Any local sewing or craft store will stock spools of heavy-duty black #90 UV upholstery thread and #18 chenille hand needles. Knit fabric is not prone to unraveling once properly sewn together, so it's not necessary to melt or sear cut edges. A little silicone or butyl caulk can be applied to better protect the repair, but never present an open flame anywhere near a panel. Longer tears and larger holes are best reinforced with 'hem tape' batten webbing (not adhesive) on a home sewing machine with a #16 or #18 ball-point needle. It might be possible to create a flat sewn 'patch' by laying one piece of webbing on both sides of the panel, but a 'pinch pleat' is much stronger and longer lasting. For a pinch pleat, the fabric is 'pinched' into a creased 'pleat' with solid webbing folded atop and sewn. Always test your sewing machine tension settings on a folded piece of webbing before stitching. We do not sell batten webbing in less than full 300 foot long rolls (see below) but you can search online for: "3 inch wide black polypropylene webbing strap". Note that nylon and polyester webbings do not have the same inherent UV sunlight resistance as polypropylene. Black is a better choice for longevity since it does not contain any added colorants which tend to break down in direct sunlight. Beware of fire retardant coatings.

2-3/4 inch by 300 foot rolls of black hem tape webbing

FREE Shipping contiguous 48 states only - UPS or USPS (1 roll)

Last updated on February 22nd, 2024